September 11, 2001 Corn Milling, Processing and .

Minnesota Nutrition Conference Minnesota Corn Growers Association Technical Symposium September 11, 2001 Presented by Kelly S. Davis Quality Manager

WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Minnesota Nutrition Conference Minnesota Corn Growers Association Technical Symposium September 11, 2001 Presented by Kelly S. Davis Quality Manager

Some of the terms used in this factsheet are defined in IEER''s online glossary. First discovered in the 18th century, uranium is an element found everywhere on ...

Swansoft CNC Simulator is realtime 3D CNC machine system simulation and advanced Gcode verification software. It allows the user to simulate all the CNC machine ...

The Characteristic Features of Process Costing, the industries in which process costing is applied.

Ethanol is commercially produced using either a wet mill or dry mill process. Wet milling involves separating the grain kernel into its component parts (germ, fiber ...

Milling systems. A rice milling system can be a simple one or two step process, or a multi stage process. One step milling husk and bran removal are done in one pass

CNC Simulator for Turning Milling System Description. This document contains detailed information about the features of the MTS CNC Simulator for Turning ...

Important stages of rice cultivation. Rice cultivation is a complex activity that requires a series of processes to achieve the finished product.

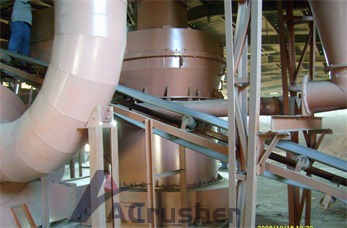

EQUIPMENT. FluidQuip, Inc. has been designing and manufacturing corn separation and grind equipment for over 25 years. Fluid Quip Process Technologies works ...

Feeding and Nutrition for Pigs Today! Lindner Feed Milling, 2012 VATAT

HOW TO USE A TYPICAL CNC MACHINE : 1. The design is loaded into the computer which is attached to the CNC machine. The computer changes the design into a ...

1. The oats are brought at harvest into the mill by the growers. They are then cleaned and dried so that they may be safely stored until they are needed.

To Our Clients. Marley Wright operate a Search Selection recruitment process, which means the bulk of our time is spent proactively sourcing contacting passive ...

Milling is the most common form of machining, a material removal process, which can create a variety of features on a part by cutting away the unwanted material.

calculators, engineering, mechanical, electrical, electronics, design, construction, manufacturing, consultant, layout, software, chemical, plastic, polymers

iterative design cycles. video iterative design click below pdf file click here for an introduction to the iterative design process (preparation for changes to ...

3 Dewatering, Germ Washing, and Fiber Washing Dewatering and Germ Washing Economical corn wet milling practice requires dewatering of the supply

Renewable Fuels Association How Ethanol is Made? ... Wet Mill Ethanol Process. In wet milling, the grain is first separated into its basic components through soaking.

Milling rough lumber for workshop projects saves money, and it also opens up more creative possibilities than standard, predressed wood. That''s why Art Mulder ...

CNC machine shop specializing in precision machining, milling, and turning. Shop equipment photos and capabilities, and product sample photos.

In materials science, the solgel process is a method for producing solid materials from small molecules. The method is used for the fabrication of metal oxides ...

10 Tips for CNC Router Aluminum Cutting Success 10 Things Beginning CNC Milling Machine Users Need to Succeed Secrets of Going From CAD, Image, DXF, or STL to ...

Great Dives Start Here. How can simply turning the tank valve and pressurizing the first stage of your new Atomic regulator be a lifechanging experience?

High Speed Milling Machines High speed machining is characterized by low cutting forces and high metal removal. High Speed Milling is a technique used in the CNC ...

WhatsApp)

WhatsApp)